Save on maintenance, replacement costs and process control

New installed energy sources and power electronic equipment have generally deteriorated the power quality of your network. While it may not be directly visible some signs may alert you. Let us give some few examples from our daily life.

- A breaker opens and the electronic equipment beyond the breaker stops. The breaker opened because of the occurrence of an unexpected harmonic current from equipment nearby.

- Harmonics accelerate the ageing of the capacitors. Capacitor banks capacities reduce constantly and fail more frequently.

- The DSO (Distribution Service Operator) has lowered the average mains voltage. While it stays within the tolerance most of the time, voltage dips are now regularly below the lower limit of most electronic control equipment.

- The mains went off but the generator did not start, causing a major business disruption and cost. The capacitive reactive energy from the cumulated loads was too high.

- Electrical motors make more noise than usual. The noise is the result of harmonics on the stator.

These examples are visible but non-power quality affects your equipment insidiously reducing their lifetime and increase your maintenance costs. As your business infrastructure and its electrical environment are constantly changing, you should regularly analyze your power quality, discuss the results and bring simple remedies when necessary.

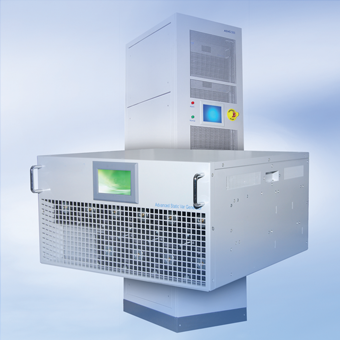

Reactive energy generators

Replace your capacitor banks (see comparison)

Reduce your electricity bills

Secure the operation of your generator

Voltage regulators and Sag Fighters

No dips, no maintenance, no costs

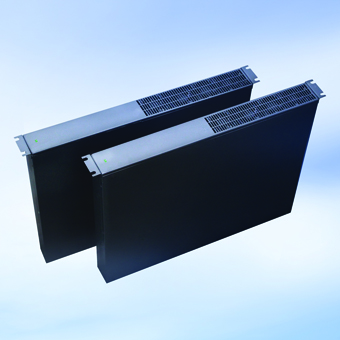

Active harmonic filters

Reduce the risk of process disruption